Christian Duessel

My portfolio

My name is Christian Duessel, and I am a Materials Science and Mechanical Engineering (with a CIR (Control, Instrumentation, and Robotics) concentration) double major at MIT (Class of 2025) from Dallas, Texas. Please see below for my engineering portfolio. My resume is linked here, with my contact information.

Adaptive Vision and Robotics

My summer 2023 internship. Adaptive VR is a newer wing to the larger Adaptive Resources, a manufacturing consulting company headquartered in Dallas, TX. This summer I went onsite at three manufacturing plants, learned the basics of PLC programming, and created an HMI/pattern recognition software from scratch. The largest project I worked on was a cobot palletizer (a new offering for Adaptive VR).

Palletizing Robot

I joined this project 6 weeks before the FAT (Factory Acceptance Testing). I helped finish/troubleshoot the hardware, designed calibration tools, wrote box-pick control algorithms, troubleshooted singularities/reach constraints/speed requirements, installed onsite, and trained operators. I also created a more cost effective hardware for the next palletizing robot.

Installed and in production at factory.

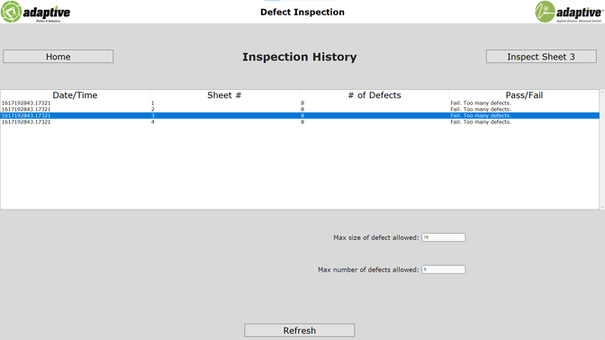

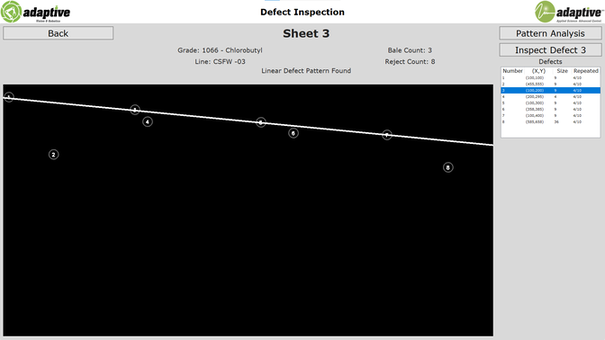

Defect Pattern HMI

In Python, I created an HMI (Human Machine Interface) for an inspection station at a manufacturer of sheet material. This program interfaces with a dolly-mounted Keyence camera that will take several pictures as it sweeps over the part. The job of the HMI program is to recieve these pictures over FTP, compile and summarize the data, analyze defect patterns, and label each part as GO or NO-GO.

Defect map with equidistant linear pattern highlighted.

1990 Jeep Cherokee XJ

My first car, and first time working on cars. Bought it summer 2023 and towed it back from Orlando... Oklahoma. It has the 4.0L I6, 5 speed manual, and pioneer trim.

Exhaust

The car came with a large exhast leak, right at the manifold. After a week and a half of figuring out what vacuum tubes go where, bending into funny shapes to remove

bolts, and grinding through several rust-welded fastners, the old manifold came out. It will hang on my wall.

Note the "small" leak (at my storage unit, here).

This repair required a deep dive.

Steering

The Jeep also "featured" some very floaty steering (see right). This fix required a couple proprietary tools and a few junkyard dives, but the wheel is now firm.

I fixed the high beams while I was at it.

The steering still felt fairly light, and I did experience some death wobble. When I went to add some positive caster, I discoverd bent tie rods and control arms. I ended up replacing all the steering linkages, track bar, and control arms.

I don't think it's supposed to do that.

Brakes

What started as a routine brake fluid flush turned into a three-day venture where I ended up replacing the master cylinder and bending up a new brake line. Don't ask.

Body

Fixed rust spots on the roof, as well as put in a custom blue-grey corduroy headliner. Totally 90s.

Before during and after. Added in Radiant Barrier insulation while I was at it.

Misc

I bought new seatbelts and welded on the brackets. My mom was happy about this.

Got a pretty bad powersteering leak and broke my Dad's one rule: "That piece of crap better not leak on the driveway". Replaced the low and high pressure lines to fix it.

The coolant looked more like coca-cola, so I flushed the system with a chemical flush and DI water. I also changed the oil, power steering fluid, and transmission fluid.

Replaced the broken ignition cylinder.

Did a LOT of cleaning and fixing of small rattles.

MIT Motorsports

Suspension Tabs/Jig

I was assigned to the design and manufacturing of the suspension tabs and their welding jig. This required navigating small adjustments of suspension points, design/validation/manufaturing of suspension tabs, design/manufacturing of the reversable jig, and tab grinding. When we weld the frame of the car, we cannot be certain it doesn't distort under the heat. We also need the suspension points to be accurate to the design, otherwise we risk safety and performance. Therefore, we need to jig the tabs and grind their tight fit to the frame after it is welded.

Suspension tab ready to be cleaned/welded

Frame Modal Analysis

Conducted frame modal analysis for use in the design presentation to judges. Created a series of 1D meshes to approximate the tubes of the frame, and 2D meshes to include body panels.

Machining

I spent many hours in the shop helping with assorted machining tasks in additon to my projects. Pictured are two examples: rear wheel hubs and brake pedal base block for MY22.

Et Manus

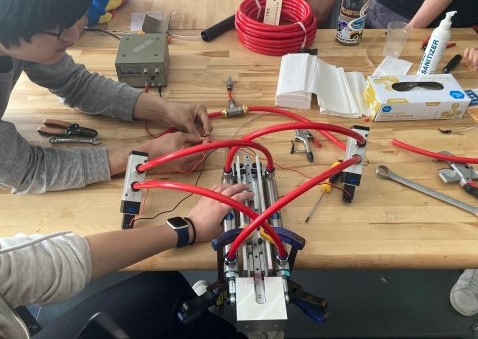

The Discovery Channel's Mythbusters packed up shop in 2019. With the help of some friends, I started MIThbusters. We intend to pick up where the Mythbusters left off. Our first myth came from the popular video game Minecraft. In the game, the player's first task is to punch a tree (with their "hand") to obtain wood. We wanted to see if this is even possible, and how long it would take to punch through a living oak tree. Instead of putting our hands on the line, we decided to build a punching machine to replicate a human punch.

We dubbed our design the "Et Manus", latin for "and hand" (inspired by our school motto of "Mens et Manus"). Pictured: first full speed test run versus an apple.

Smooth Operator

Smooth Operator V2.5 Mounted on Rowing Machine

This was my first real engineering project. It is an attachment for a Concept2 Model D/E rowing machine. The idea is to take the rigid footplates and instead float them while linking their movement. If one foot moves away from the user, the other moves toward the user. In this way, the user would be forced to balance the power between the left and right side of their body. This has potential applications in injury prevention, increased speed, and physical therapy. I filed for a patent in August 2021 and I am working through examiner comments delivered August 2023.

Through this project, I gained experience in woodworking, CAD (F360), welding, brazing, lazer cutting, plasma cutting, and maching.

MIT Toy Product Design

I took MIT's Toy Product Design class (2.00b) in the spring of 2022. I selected 3 projects to display. The first is a game I created called a MorseCodeSpyBox. The idea is that using the 4 buttons on the hat to repeat patterns, users could learn to Morse Code in a fun way. There are 3 different game modes to choose from, just don't touch the red button! The second project is a simple pull/push bunny toy with oblong wheels to create a "hop."

We created a main project as a team: "SquishTalkies." The idea for SquishTalkies was stuffed animals that users could send voice recorded messages with. Children could communicate with relatives and friends in an asynchronus phone-free way. The term culminated in a live streamed group "Playsentation." Pictured is my teammate and I after our successful playsentation holding the SquishTalkies. You can watch here (2:32:55).

Motus Labs

Testing

Laminate disk pack test stand

Static moment test of crossroller presser flanges

Magnet wire heat test for thermal resistance

I worked as a testing engineer and design engineer intern at Motus Labs during the 2022 summer. Motus Labs is a Dallas startup working on new gearbox technology for robotic arms. As a testing engineer, I helped assemble and conduct testing on laminate disk packs (a component of the gearbox), pictured left. I also created a temporary static moment test for stiffness for crossroller bearing presser flanges and I designed a magnet wire heat test for thermal resistance. I worked on matlab scripts to interpret data from the existing test benches, and I designed 2 permanent test benches.

Design

As a design engineer, I took the existing gearbox design and scaled it down to fit a smaller 75mm size. I also ideated and designed the next iteration on the main gearbox for Motus Labs. I also helped with some assembly fixtures for oil seals and orings.

Initial design of ML2000-75

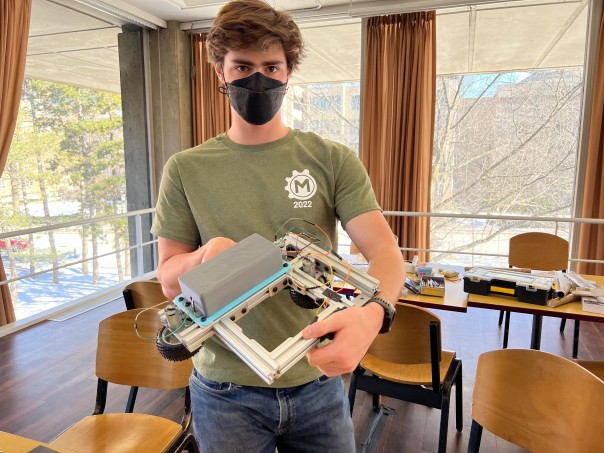

MakeMIT was a one-day hardware hackathon. Given an assortment of common components, my team of three built Rail Snail. Rail Snail was a portable device wheelchair users could carry that would attach to a railing and pull them up the ramp. We created the frame from 8020 components and used an Arduino with a simple relay circuit. Admittedly, the available 9v batteries cannot pull a person up a ramp, but it is always fun to brainstorm and make an idea come to life!

For our second year, we built Loco-mo-ton. Our teammate Faris broke his leg the week prior to the competition. He was wheelchair bound and slow.

We designed a linkage mechanism so that instead of using his (weak) arms, he can use his strong, burly chest to bench his way to class.

We won a $1000 prize and custom action figures by FormLabs. You can read more here.

I took MIT's Electronics For Mechanical Systems (2.678) in the spring of 2022. In this class, we learned a fundamental understanding of electronics from the ground up. In the labs we created everything from simple audio amplifiers to a motion tracking webcam. The final project for the class was an autonomous robot race around a complicated track. My partner and I ended up winning the competiton and got this "Grand Champion" certificate.